THE STUDIO

Every creative work begins with a lengthy field study. After hundreds of hours spent sketching in zoos, stud farms, museums, and circuses, Michel BASSOMPIERRE has memorized the volumes, plans, muscles, characteristics, and spirit of each subject.

These sketches will be transformed into models. Clay lends itself particularly well to this work of research and analysis of forms. These small subjects will then be enlarged to create bronze and marble sculptures.

.jpg)

“It takes me a month or two to analyze my subject. But to fully master it, it takes about ten years. And to understand sculpture, it takes 50 years.”

THE CREATIVE PROCESS IN THE STUDIO

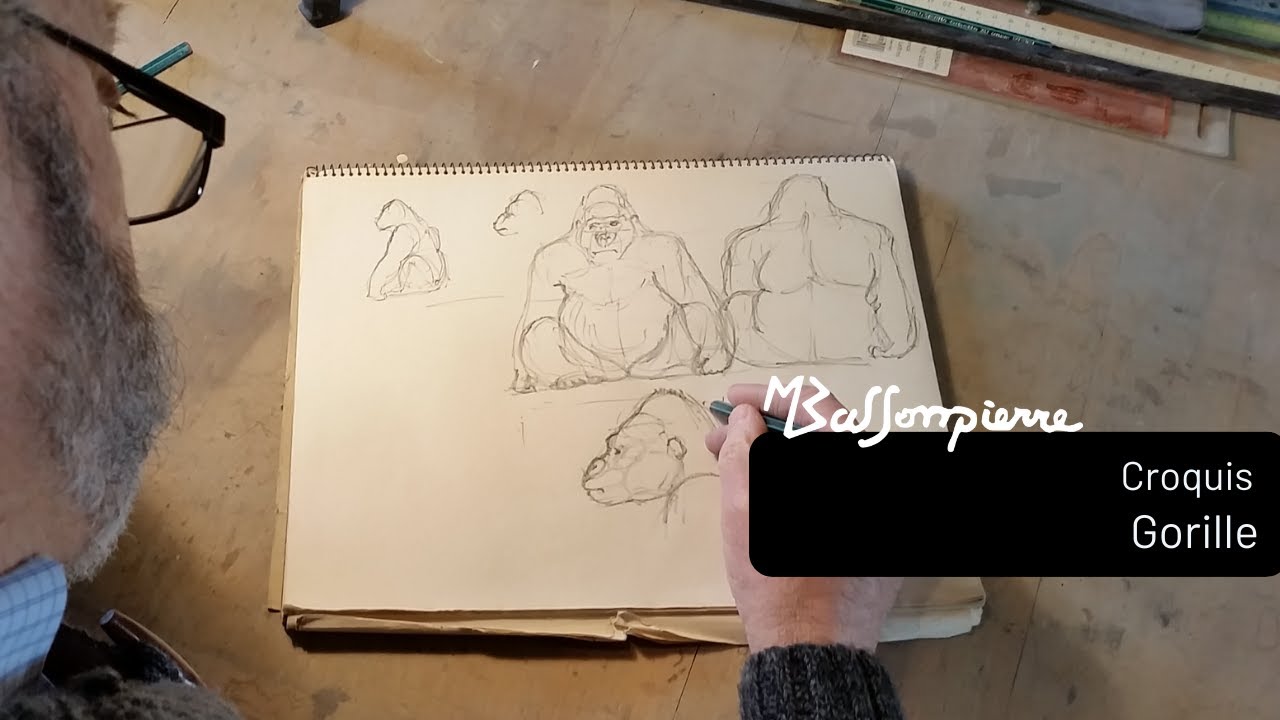

1. DRAWING

Before sculpting a piece, Michel BASSOMPIERRE always makes sketches. He depicts his subject from several angles or creates a “transparent” drawing to ensure that the composition is correct.

2. MODELING

Like his illustrious predecessors, Michel Bassompierre is a modeler who loves working with clay.

He first creates a clay model measuring 10 to 20 cm in height. If it matches what he had imagined, if it is well composed and balanced, he moves on to enlarging his model, which will measure between 30 and 40 cm.

3. MOLDING

Before it dries, the sculpture is molded to make a plaster copy.

After several weeks of drying, the sculpture is fired for several hours at a temperature of 850°C. This gives it its brick color and makes it more resistant.

4. PLASTER

When it comes out of the mold, the plaster cast has many imperfections. A long process of sanding or adding material is then necessary. Unlike clay, plaster allows for a very fine finish.

After dozens of hours of work, the desired result is finally achieved: beautiful curves where shadow never collides with light.

The final step is to cover the plaster with a layer of gray primer, which hardens its surface and ensures that the lines are perfect. The plaster is then ready to be sent to the foundry...

TOOLS

The tools used for modeling and plastering have remained virtually unchanged since ancient times.

Since studying at the Beaux-Arts more than 50 years ago, Michel BASSOMPIERRE has continued to use the same small knife when sculpting clay.

Croquis - Gorille - Michel BASSOMPIERRE

VIE D'ARTISTE - Les sculptures de Michel BASSOMPIERRE (Interview)

Création - "Les Saumons n°1" - Michel BASSOMPIERRE (Sculpture en bronze)

Modelage - Ours : "Le Miel n°6" - Michel BASSOMPIERRE

Modelage - Cheval : "Le Paturon n°1" - Michel BASSOMPIERRE

Modelage - Gorille : "Le Dos Argenté n°6" - Michel BASSOMPIERRE

Modelage - Ours polaire : "Le Trou d'Eau n°1" - Michel BASSOMPIERRE

Modelage - Tête d'Ours - Michel BASSOMPIERRE

.jpg)

AT THE FOUNDRY

1. PLASTER

Once completed in the studio, the plaster work is sent to a foundry to be cast in bronze.

Michel BASSOMPIERRE's bronzes are always cast in 12 copies (8 + 4 artist's proofs). They are therefore original works of art. Beyond 12 copies, they are referred to as "multiples ."

2. CREATION OF THE MOLD

Several layers of liquid elastomer (a highly elastic material) are applied to the work with a brush to facilitate demolding. This flexible impression is held in place by a plaster cap reinforced with sisal (a plant fiber used in the manufacture of ropes).

.jpg)

3. MAKING THE WAX MODEL

The inner wall of the mold is covered with melted wax, in layers, until the desired thickness is achieved. This thickness of 3 to 4 mm will correspond to the thickness of the bronze after casting. Once the wax has cooled, it is removed from the mold and reworked to correct any defects.

4. INSTALLATION OF THE FEEDING SYSTEM AND CASTING OF THE BRONZE

Wax coils are glued together to create a highly complex network of “pipes” that allow air and gases to escape and the bronze to be cast. The wax model and its network of pipes are covered with refractory plaster. A metal cylinder encloses and secures this assembly. Only one opening (called a pouring funnel) is visible at the top of the mold, designed for pouring in the liquid bronze.

5. DEMOLDING

This operation, carried out using a high-pressure water cleaner, consists of breaking the plaster mold to reveal the “cast bronze.”

The mold is then heated to 700°C to remove the wax and any traces of moisture.

The molten bronze (at 1140°C) is poured into it.

Bronze is an alloy composed of tin and copper that art foundrymen keep in ingot form. Its composition varies, but generally includes between 70 and

85% copper and 15% tin.

6. DEBURRING

This raw cast bronze is an exact replica of the wax. The network of pipes, which was made of wax before casting, is now made of bronze. Using grinding wheels and disc grinders, the chiselers cut and remove all the pipes.

7. CHISELING

The chiseler polishes the bronze using increasingly fine abrasives to bring out every characteristic detail of the original model. Michel Bassompierre's rounded works are part of what is known as “smooth polishing.” This highly demanding technique is mastered only by the best workers in the foundry.

8. BRONZE PATINA

The work can finally receive its final color, called patina. It is the result of two simultaneous actions: the application of different mixtures of metal oxides and acids to the surface of the work with a brush, and the passage of a heat source with a torch.

Depending on the desired color, a specific mixture will be applied. Without this, a chiseled, golden bronze will naturally oxidize and turn green.

Finally, a thin layer of beeswax is applied to polish and shine the patina. The bronze is now ready to stand the test of time.

.jpg)